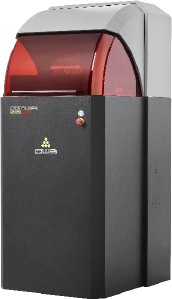

029XC

029XC is a solution for rapid manufacturing designed for medium-high

production volumes. It grants high speed, precision and an increased working

area to maximize the productivity. 029XC runs both the proprietary Nauta Plus

software (that allows the automatic generation of supports) and its special

(optional) module XCluster*,

dedicated to the easy building of trees for lost wax casting productions.

Thanks to the combination among materials, its precision and the specifically

designed software, the workflow becomes totally digital and automated. This

increases productivity, reduces time-to-market, production times and

consequently costs in the different application fields.

With extremely low running and maintenance costs, the printer has been

designed to operate continuously, always ensuring the maximum reliability and

consistency.

* Patent pending

Main Features

- Very high resolution and precision

- Fully digital and automated workflow

- Increased productivity

- Reduction of costs and production times

- TTT System – Tank Translation Technology that optimizes the wear of the resin tank

- Low maintenance costs

Specs

Technology: Laser Stereolithography

Working Area: 170 x 170 x 200 mm

Laser Source: Solid State BluEdge®

Slice Thickness: 10-100 microns (mechanical resolution, the actual value depends on the material used)

Scanning Method: Galvanometer

Software: Nauta® Plus and Fictor®

Input File Format: .stl, .slc, .nauta, .fictor, .mkr, .3dm, 3ds, .ply, .obj, .lwo, .x

Machine Size: 610 x 660 x 1400 mm

Weight: 150 Kg

Operating Temperature and Humidity: 20°-25°C / 60%

Power Supply: AC 230/115 V / 50-60 Hz

Electrical Consumption: 500W

PC Minimum Requirements: External PC included

I/O Interfaces: 1 USB port – 1 TCP/IP ethernet port

Connectivity: 1 Active internet connection

I/O Interfaces: 1 USB port – 1 TCP/IP ethernet port

Connectivity: 1 Active internet connection